|

Ningbo MaxMagnet Co., Ltd.

|

magnetic workholding

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

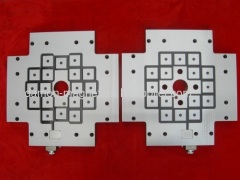

A magnetic clamping mould avoids deformation and avoid the effect of internal tension.Clamping force evenly distributed throughout the contact surface

DM-QMC is using electrical impulses to open and close magnetic mould replacement system. Using the different characteristics of different magnetic materials designed to best magnetic circuit, Through the electronic control system for the distribution of internal magnetic circuit control and conversion, Make permanent magnet field in the system itself balance, The external characterizationThe external characterizationThe external characterization is demagnetization or relaxation state; Or released into templates work surfaces, The external characterization is magnetization or mould clamping state.

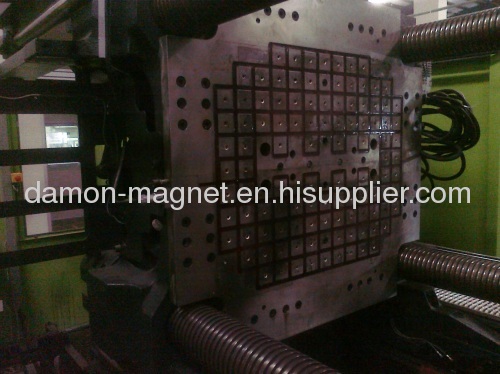

Rapid mold change - saving more than 90% mold changing and installation time, suitable for the current high-speed competive era, promoting an enterprise competition ability, being fast, on-time delivery, reducing production cost, saving production time.International latest third generation mould exchange technology, fully surpass second raditional hydraulic clamp mould device, avoided complicated high-pressure oil and gas pipeline, without template modifying, no need worry about the blackout or pay multifarious maintenance and expensive accessories expenses.

DM-QMC brings the enormous savings and convenience to different industries. Along with our continuous development, this system has installed hundreds of sets on different series of injection molding machine, punch, mould closing device.

1200T Injection Electic permanent magnetic quick mold Clamping Systems

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Magnetic Chuck

Magnetic Separator

Magnetic Toy

Magnetic Lifter

Magnetic Material

Magnetic Filter

More>>

.jpg)