|

Ningbo MaxMagnet Co., Ltd.

|

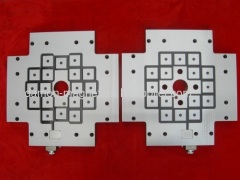

Quick Die Change System

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

- improved manufacturing flexibility

- reduction of machine down time

- better quality in molding

- reduction of inventory

A short electric pulse lasting some fractions of second activates the system securing the clamping of the mold for unlimited time without consuming electrical energy or generating any heat. Only by a subsequent electric pulse is it possible to demagnetize the system and disengage the mold that has been held exclusively by the strength of permanent magnets during the working session.

Quick Die Change System

During the Mag phase the magnetic flux is short-circuited outside the magnetic surface safely clamping the mold with a very limited magnetic depth so as not to affect any internal part of the engaged mold.

During the Demag phase the magnetic flux is short circuited inside the magnetic module frame,perfectly releasing the mold for its changeover.

A magnetic clamping mould avoids deformation and avoid the effect of internal tension.Clamping force evenly distributed throughout the contact surface, Rather than a traditional clamping press several points, Make mould injection molding, stamping out products maintain consistency.

Many installations are already done all over the world on the best machine brands either new or already in use have proven the great economical convenience in noumerous industrial sectors

DM-QMC brings the enormous savings and convenience to different industries. Along with our continuous development, this system has installed hundreds of sets on different series of injection molding machine, punch, mould closing device.

Constant force:

Each square pole of the system is an independent magnetic island made by a steel core and

surrounded on its 5 faces by "high energy" permanent magnets (AlNiCo + neodymium) able to generate

a high value of magneto motive force (m.m.f.) concentrated and constant at indefinite period of time.

The total holding force available is directly proportional to the number of magnetic poles engaged with the surface of the mold thus always predictable.

Quick Die Change System

During the Mag phase the magnetic flux is short-circuited outside the magnetic surface safely clamping the mold with a very limited magnetic depth so as not to affect any internal part of the engaged mold.

During the Demag phase the magnetic flux is short circuited inside the magnetic module frame,perfectly releasing the mold for its changeover.

A magnetic clamping mould avoids deformation and avoid the effect of internal tension.Clamping force evenly distributed throughout the contact surface, Rather than a traditional clamping press several points, Make mould injection molding, stamping out products maintain consistency.

Many installations are already done all over the world on the best machine brands either new or already in use have proven the great economical convenience in noumerous industrial sectors

DM-QMC brings the enormous savings and convenience to different industries. Along with our continuous development, this system has installed hundreds of sets on different series of injection molding machine, punch, mould closing device.

Constant force:

Each square pole of the system is an independent magnetic island made by a steel core and

surrounded on its 5 faces by "high energy" permanent magnets (AlNiCo + neodymium) able to generate

a high value of magneto motive force (m.m.f.) concentrated and constant at indefinite period of time.

The total holding force available is directly proportional to the number of magnetic poles engaged with the surface of the mold thus always predictable.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Quick Change Die

Quick Change Tools

Quick Mould Change

Quick Change Mold

Change Valve

Oil Change

More>>

.jpg)