|

Ningbo MaxMagnet Co., Ltd.

|

Quick mold Change Systems

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

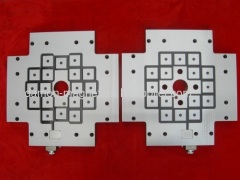

Permanent electro magnetic modules in solid steel, for the fixed and moving side, with centering ring.

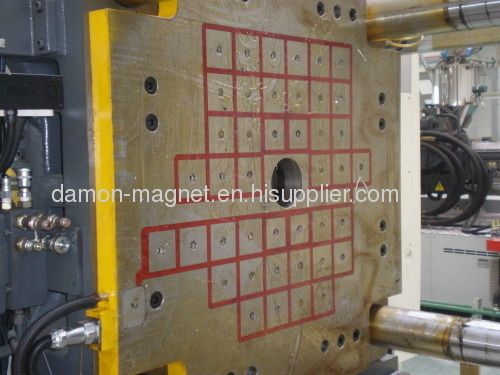

1000T Injection permanent-electro magnetic qiuck mold Clamping Systems

The machine enable will be available only when the mold is perfectly positioned and the system magnetized.The electronic control units are standard equipped with UCS current Control Systems.The electric panel is contained in standardized watertight cabinet IP54 rated.

International latest third generation mould exchange technology, fully surpass second raditional hydraulic clamp mould device, avoided complicated high-pressure oil and gas pipeline, without template modifying, no need worry about the blackout or pay multifarious maintenance and expensive accessories expenses.

Remote control:

All the operating functions are activated and controlled by a dedicated remote push-button conveniently located; the mold setter oversees the whole mold change procedure from outside the machine in full

safety. A specific safety key enables the "mold-set-mold" procedure and the Mag/Demag cycles.

DM-QMC brings the enormous savings and convenience to different industries. Along with our continuous development, this system has installed hundreds of sets on different series of injection molding machine, punch, mould closing device.

The machine enable will be available only when the mold is perfectly positioned and the system magnetized.The electronic control units are standard equipped with UCS current Control Systems.The electric panel is contained in standardized watertight cabinet IP54 rated.

International latest third generation mould exchange technology, fully surpass second raditional hydraulic clamp mould device, avoided complicated high-pressure oil and gas pipeline, without template modifying, no need worry about the blackout or pay multifarious maintenance and expensive accessories expenses.

Remote control:

All the operating functions are activated and controlled by a dedicated remote push-button conveniently located; the mold setter oversees the whole mold change procedure from outside the machine in full

safety. A specific safety key enables the "mold-set-mold" procedure and the Mag/Demag cycles.

DM-QMC brings the enormous savings and convenience to different industries. Along with our continuous development, this system has installed hundreds of sets on different series of injection molding machine, punch, mould closing device.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Quick Change Mold

Quick Change Tools

Quick Mould Change

Quick Change Die

Change Valve

Oil Change

More>>

.jpg)