|

Ningbo MaxMagnet Co., Ltd.

|

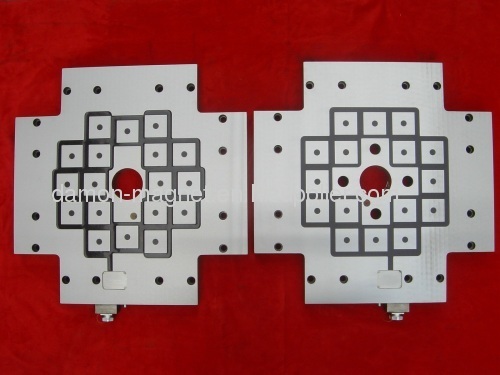

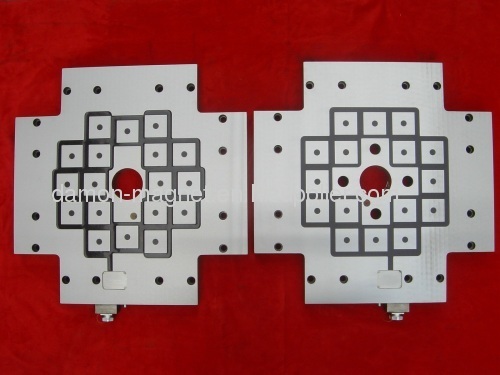

Electro Permanent Magnetic Chuck

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

DM-QMC is maintenance free, due to it doesn't present any mechanical component inside.

DM-QMC is mainly designed against long clamping mould time, complex operation and low security of injection molding machine, punch and mould closing device. This system uses permanent-electro magnetic plate as fixed and moving plate. It can clamp or take mould through MAG/DEMAG process by simply turning safety key (removable) and push MAG/DEMAG button, accomplishing mould-changing truly in 3 minutes. It can be installed on new machine as standard equipment to sale to final customers; also can be on the traditional machine, adding 3 minutes mould change function but not changing original structure, which is practical and convenient. DM-QMC is currently the most complete answer to the growing requirements of concepts like JIT (Just In Time) and SMED (Single Minute Die Exchange) in all advanced manufacturing process to face smaller production batches and wider product ranges, by offering.

Electro Permanent Magnetic Chucks for 700T Injection

DM-QMC is using electrical impulses to open and close magnetic mould replacement system. Using the different characteristics of different magnetic materials designed to best magnetic circuit, Through the electronic control system for the distribution of internal magnetic circuit control and conversion, Make permanent magnet field in the system itself balance, The external characterizationThe external characterizationThe external characterization is demagnetization or relaxation state; Or released into templates work surfaces, The external characterization is magnetization or mould clamping state.

During the Mag phase the magnetic flux is short-circuited outside the magnetic surface safely clamping the mold with a very limited magnetic depth so as not to affect any internal part of the engaged mold.

During the Demag phase the magnetic flux is short circuited inside the magnetic module frame,perfectly releasing the mold for its changeover.

Electro Permanent Magnetic Chucks for 700T Injection

DM-QMC is using electrical impulses to open and close magnetic mould replacement system. Using the different characteristics of different magnetic materials designed to best magnetic circuit, Through the electronic control system for the distribution of internal magnetic circuit control and conversion, Make permanent magnet field in the system itself balance, The external characterizationThe external characterizationThe external characterization is demagnetization or relaxation state; Or released into templates work surfaces, The external characterization is magnetization or mould clamping state.

During the Mag phase the magnetic flux is short-circuited outside the magnetic surface safely clamping the mold with a very limited magnetic depth so as not to affect any internal part of the engaged mold.

During the Demag phase the magnetic flux is short circuited inside the magnetic module frame,perfectly releasing the mold for its changeover.

A magnetic clamping mould avoids deformation and avoid the effect of internal tension.Clamping force evenly distributed throughout the contact surface, Rather than a traditional clamping press several points, Make mould injection molding, stamping out products maintain consistency.

Rapid mold change - saving more than 90% mold changing and installation time, suitable for the current high-speed competive era, promoting an enterprise competition ability, being fast, on-time delivery, reducing production cost, saving production time.

Many hundreds of installations of DM-QMC have been put in operation all over the world by the most prestigious molding companies active in different fields.

Many hundreds of installations of DM-QMC have been put in operation all over the world by the most prestigious molding companies active in different fields.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Permanent Magnetic Chuck

Magnetic Chuck

Permanent Magnet Chuck

Chuck

Electro Permanent Magnet

Key Chuck

More>>

.jpg)